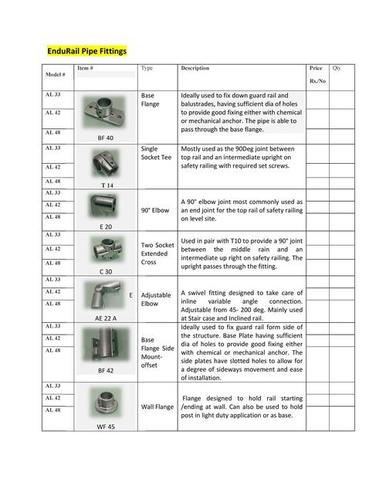

EnduRail Pipe Fittings

EnduRail Pipe Fittings Specification

- Technics

- Casting

- Style

- Modular

- Frame Material

- Aluminium

- Feature

- Corrosion Resistant, Durable, Easy Installation

- Color

- Natural/Customized

- Size

- 1/2, 3/4, 1, 1-1/4, 1-1/2, 2, and custom sizes

- Arm Length

- Standard/Custom

- Gross Weight

- Depends on size and model

- Width

- Standard or customized

- Type

- Pipe Fittings

- Material

- Aluminium Alloy

- Surface Treatment

- Powder Coated

- Height

- Standard or customized

- Length

- Standard/Custom

- Processing

- Casting/Precision Machining

- Standards

- Complies with EN/ISO standards

- Connection Type

- Slip-On/Clamp-On

- Usage

- Handrails, Guardrails, Industrial Railings, Structural Frames

- Temperature Resistance

- -40°C to 80°C

- Finish

- Smooth/Matte

- Packaging

- Carton Box or as required

- Load Bearing Capacity

- Up to 1200kg (varies per fitting)

- Application

- Industrial, Commercial, Residential

EnduRail Pipe Fittings Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Day

- Delivery Time

- 1 Week

About EnduRail Pipe Fittings

Why EnduRail / Should You Weld?

EnduRail Pipe Fittings vs. Fabricated Welding

Comparison Chart

In this sections we will compare many different aspects of pipe railing installation and maintenance.

Installation | EnduRail Railing | Traditional Welded Rail |

| Specialized Labor | No, Simple to Install | Yes, Professional Labor Union Employee |

| Time | Typically it would take 2 people 8 hours to install 100 ft. of railing. | Varies on availability and skill level. |

| Special Permits | None | Hot Permit Required |

| Safety Factor | Use of simple tools such as drill, hammer, and allen wrenches. | Welding creates a greater potential for bodily harm. |

Maintenance | EnduRail Railing | Traditional Welded Rail |

| Breakage | The systems modular components allow for the broken section to be replaced by loosening the surrounding fittings and replacing the broken fittings and pipe. | A professional welder must replace the affected section |

| Rust | The EnduRail system components are anodized or Powder Coated to resist corrosion. EnduRails railing are known to last for 20 years without showing the least bit of rust. | Because galvanization is removed during the installation processes, welded connections and ground fixings are known to show rust under a two year period. |

Compliance | EnduRail Railing | Traditional Welded Rail |

| OSHA | When installed properly railings built with our fittings exceed OSHA standards. | Can be constructed to OSHA Specification |

Versatile Slip-On Pipe Fittings

EnduRail pipe fittings offer an adaptable solution for constructing robust railings and structural frames across industrial, commercial, and residential spaces. The slip-on/clamp-on design ensures swift assembly without welding, bolting, or threading, making it ideal for both new installations and retrofit projects. Whether its a stairway guardrail or a safety railing, EnduRail delivers modular connectivity and security.

Engineered to Last

Constructed from premium aluminium alloy and finished with durable powder coating, EnduRail fittings exhibit remarkable resistance to corrosion and damage from harsh environments. With a temperature endurance from -40C to 80C and a maximum load-bearing capacity of 1200kg (varies per fitting), these components are built to support demanding applications while retaining their aesthetic appeal.

FAQs of EnduRail Pipe Fittings:

Q: How are EnduRail Pipe Fittings installed?

A: EnduRail Pipe Fittings use a user-friendly slip-on or clamp-on connection method. This enables quick assembly without special tools, welding, or threading, making them ideal for efficient installation and adjustments on-site.Q: What standards do EnduRail Pipe Fittings comply with?

A: These fittings are engineered to comply with EN/ISO standards, ensuring quality, safety, and interoperability in a variety of global industrial and commercial applications.Q: When should I use EnduRail Pipe Fittings?

A: EnduRail Pipe Fittings are suitable for projects in need of handrails, guardrails, structural frames, and industrial railings. They can be used in new constructions, renovations, or retrofits, both indoors and outdoors.Q: Where can EnduRail Pipe Fittings be applied?

A: EnduRail fittings are versatile and can be used in industrial, commercial, or residential environmentssuch as factories, warehouses, offices, public buildings, and private residenceswherever modular rail systems are required.Q: What is the typical process for customizing EnduRail fittings?

A: Customization involves selecting the required size, arm length, finish, color, and dimension specifications. The fittings are then produced through casting and precision machining to meet your exact project needs and delivered as per packaging preferences.Q: What advantages do EnduRail Pipe Fittings offer over traditional fittings?

A: EnduRail Fittings provide superior corrosion resistance, durability, and ease of installation compared to welded or threaded systems. Their modularity allows for flexibility in design and quick modifications, saving time and reducing labor costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Railing Category

Machinery Railing

Minimum Order Quantity : 1 Set

Surface Treatment : Powder Coated

Width : 50 mm

Material : Other, Mild Steel

Height : 1200 mm

Industrial Guard Rail

Price 2500 INR

Minimum Order Quantity : 1 , , Set

Surface Treatment : Powder Coated

Width : 150 mm

Material : Other, Mild Steel

Height : 1200 mm

Municipal Water Treatment Railing

Minimum Order Quantity : 1 Set

Surface Treatment : Other, Galvanized and Powder Coated

Width : 50 mm

Material : Other, Mild Steel

Height : 1000 mm

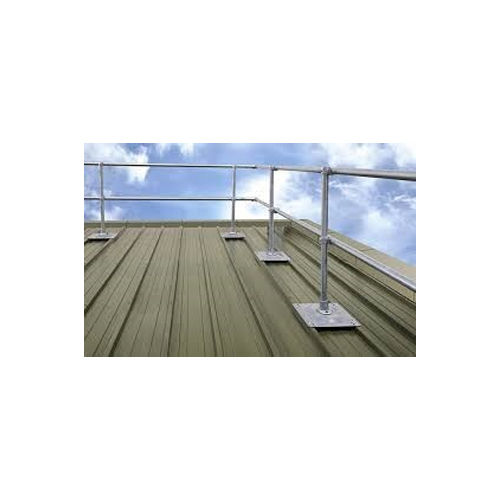

Rooftop Safety Railing

Minimum Order Quantity : 1 Set

Surface Treatment : Other, Galvanized / Powder Coated

Width : 40 mm (Pipe Diameter)

Material : Other, Mild Steel

Height : 1200 mm

|

CHEMEY MECHATRONICS LLP

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry